National Exhibition and Convention Center(Shanghai)

NECC(Shanghai)

No.333 Songze Avenue Shanghai

Booth Number:51V50

For latest updates follow us on

FIC exhibition in the food additives and ingredients industry with the strong support of colleagues, after more than 20 years of cultivation and development, has become the world’s well-known food additives and ingredients industry brand exhibition, much favored by domestic and foreign industry colleagues. Natural and functional products, mechanical equipment and testing instruments exhibition area, comprehensive products exhibition area, flavor and flavoring exhibition area and international exhibition area together form the food industry raw and auxiliary materials, food industry machinery and equipment, food industry innovation technology three sections, the exhibition content is more comprehensive, more professional, more convenient for food enterprises one-stop procurement. During the same period, the food academician series Summit Forum on the three themes of machinery and equipment to promote the development of the food industry, scientific and technological innovation to lead the future, and regulations and standards to ensure the healthy development of the food industry and more than 30 wonderful new product and new technology conferences, gathering authoritative views of the industry and scientific and technological innovation achievements, providing strong momentum for the development of the industry.

Beijing Golden Color Tech Co., Ltdgrasps the opportunities of the times and has developed the automatic printing system, Flavours Liquid Automatic Dispensing System, automatic distribution system of dyeing liquid, automatic laboratory sample distribution system and other automation systems. The printing machine pigment paste online collection and database management, spectrophotometry and other system software. Products strive to be highly intelligent, and achieve three major functions: to improve the accuracy of color; reduce dependence on labor; to meet individual needs. This helps customers minimize manufacturing costs.

Produced by our company Flavours Liquid Automatic Dispensing System is equipped with high-precision electronic scale imported from Germany. The whole process of dispensing is controlled by computer, which eliminates the influence of human factors and greatly improves the rate of first-class products. 2. Process cohesion reliability and stability improvement system, which records all the relevant data of fragrance deployment, to ensure the process cohesion reliability and stability.3. Computer database for formula, inventory management formula inventory management system can quickly and accurately query the historical formula data, quickly make a production plan, greatly improve the production efficiency, so that the production process is easy to manage. 4. Increasing production flexibility and practicality of the system has the very high flexibility in configuration, can according to the company’s production process and production environment and the actual needs of customers, quickly adjust production process parameters, production quickly, and can be calculated according to the size of the order through software requirements, by how much we do use production, as you want to do. 5. Reduce the cost of computer calculation formula, flavours liquid material dosage, not only improve the work efficiency, and control the consumption, can reduce more than 15% of the waste; Operator requirements reduced by 30%; The stability of product quality is improved and the rejection rate is greatly reduced. 6. Environmental protection to reduce waste, clean working environment, less pollution.

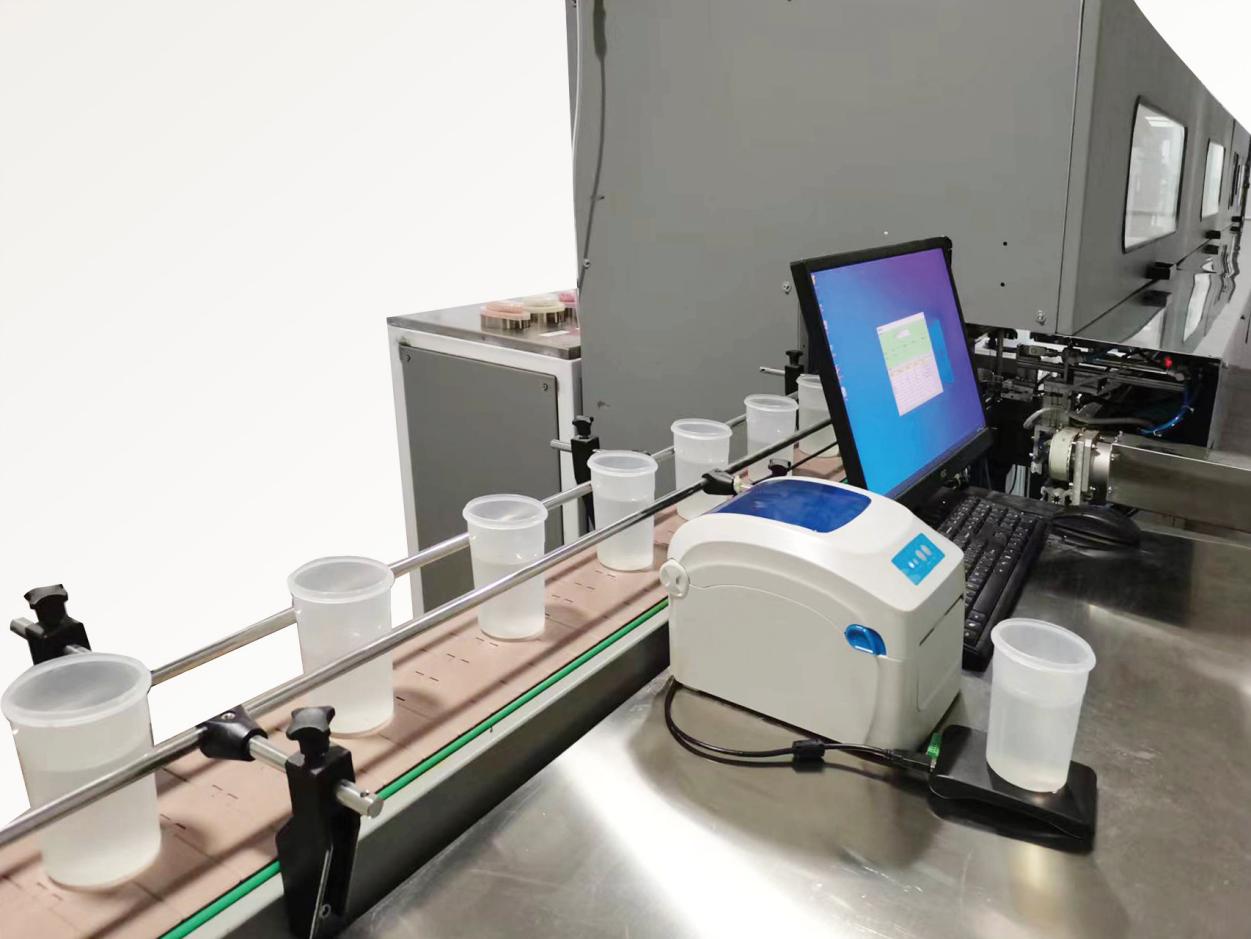

Flavours Sample and Powder Dispensing System

1. Multi-cup linkage, parallel one-stop dispensing, uninterrupted production, greatly improve the proofing efficiency;

2. Multi-variety compatible, dispensing valve can be extended to more than 200 kinds;

3. The use of 0.001g electronic balance, high precision dispensing, can meet all kinds of production needs;

4. With 16 head stirring device, the efficiency is further improved;

5. Label production mode, proofing and color change process operation is simple;

6. Powerful software, can achieve seamless docking with large-scale production equipment, data sharing;

7. Can be connected with the enterprise production management system, to achieve planned production, make the whole printing production process more orderly, higher production efficiency

Book a meeting with us

If you prefer to set aside a specific time to meet face-to-face, write to us dispensingsystem@gmail.com

Shanghai National Convention and Exhibition Center, Booth No. 51V50

Post time: Feb-28-2024