Dispensing System Dissolving Mixer

The dispensing head is equipped with a high speed stirrer. Once the dispensing of dye paste is completed, the mixer will start mixing at high speed. The well mixed paste will then be transferred to a buffer tank near to dye tank. The weighting tank (cylinder) comes with an automatic washing system to clean the weighing tank and mixer when the transferring has been completed. This can ensure that no dye residue is left and it is thoroughly clean. The pump and the pipeline will also be flushed, user can set the number of flushing time and length of each flushing through the software to ensure the weighing tank, transferring pump, pipeline and 3-way valves are completely clean and no dye residue left. Flushing water will be discharged into the buffer tank and can be measured by the weighing scale, so the bath ratio of the dye paste in the buffer tank can be controlled

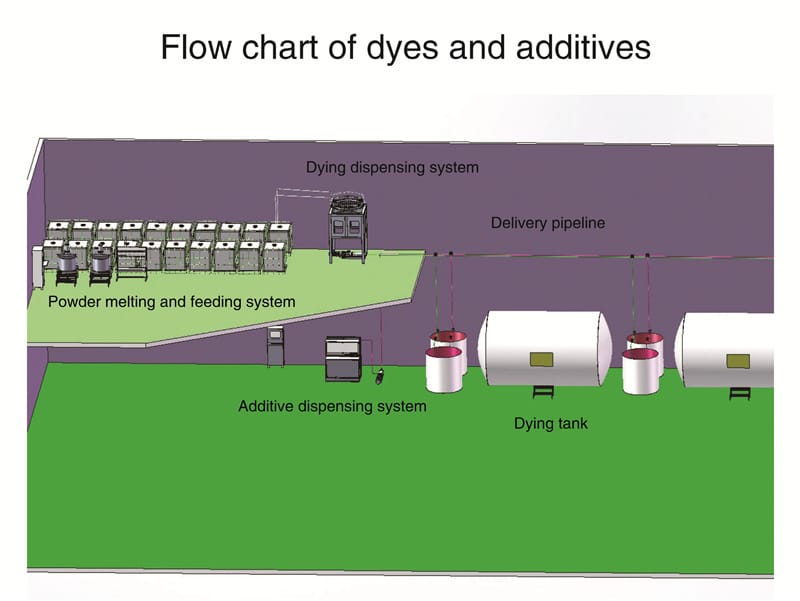

Principle

◆ Fully automatic and accurately distributes the dye and sends it directly to the auxiliary buffer tank next to the machine.

◆ Automatic dispensing of dyes reduces errors caused by manual weighing.

◆ Automatically clean the transferring line to ensure that the pipeline is clean.

Parameter

High precision dyeing valve: 12-60

Dyeing accuracy : 1g (powder accuracy 0.2g)

Piping line: Inner polished food grade sanitary tube

Gravimetric

● Imported high-precision electronic scale, no adjustment required, accurate and reliable.

● The key components of the product are imported products with high reliability.

● Single material filling; accuracy is high.

● Material saving and reduce pollution.

● Easy maintenance and possibility to expand.

● Safe, reliable and economical.

Parameter

◆ Dispensing accuracy ±1g

◆ Formulation additive neutralization and stable configuration capacity 30L/min

◆ Water flow following site environment)

◆ Auxiliary single delivery minimum amount 1g

◆ Maximum transferring viscosity 60000MPa.s